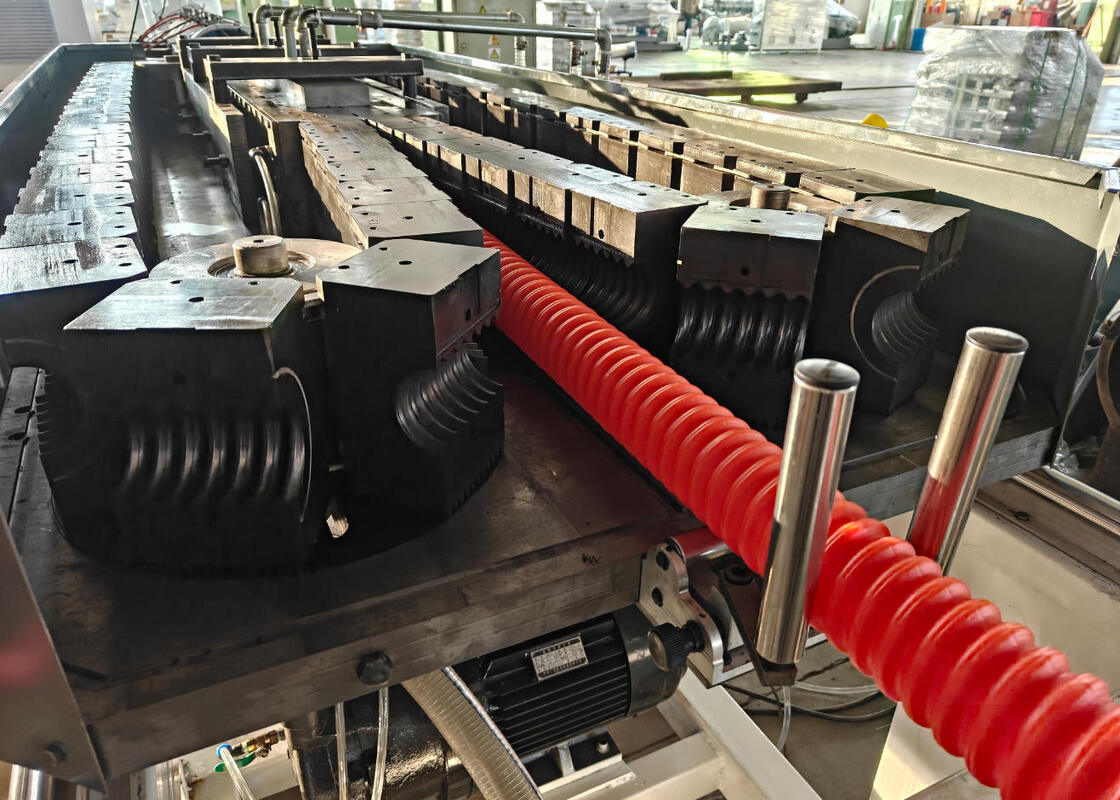

Apparecchiatura di produzione per tubi corrugati a parete singola con motore principale Siemens

La linea di produzione di tubi corrugati a parete singola in HDPE è un sistema di estrusione all'avanguardia progettato per soddisfare le crescenti esigenze dell'industria manifatturiera di tubi in plastica. Questo sistema di estrusione avanzato è progettato con precisione ed efficienza, offrendo ai produttori la capacità di produrre tubi corrugati di alta qualità adatti a varie applicazioni, tra cui drenaggio, irrigazione e protezione dei cavi.

Controllo e automazione avanzati

Il cuore della linea di produzione è un sofisticato sistema di controllo PLC (Programmable Logic Controller), che garantisce un'automazione, una stabilità e una facilità d'uso ottimali. Il sistema di controllo PLC consente il monitoraggio e la regolazione precisi di tutti i parametri critici durante il processo di estrusione, garantendo una qualità costante del prodotto e riducendo i tempi di inattività.

Capacità di produzione versatili

Il sistema è appositamente progettato per produrre tubi corrugati a parete singola e doppia, offrendo ai produttori flessibilità nell'offerta di prodotti. I tubi a parete singola sono noti per le loro proprietà leggere e l'eccellente flessibilità, mentre i tubi a doppia parete offrono una maggiore resistenza strutturale e durata per ambienti esigenti.

Prestazioni del motore Siemens di alta qualità

Caratterizzato da un motore principale Siemens rinomato per la sua affidabilità, efficienza energetica e prestazioni robuste, questo sistema aziona la macchina corrugatrice con alta precisione, garantendo un funzionamento regolare e una lunga durata riducendo al contempo il consumo di energia e i costi di manutenzione.

Caratteristiche principali

- Nome del prodotto: Linea di estrusione di tubi corrugati a parete singola

- Modalità di raffreddamento: Raffreddamento ad acqua per un efficiente controllo della temperatura

- Sistema di controllo: sistema di controllo PLC avanzato per un funzionamento preciso

- Pacchetto di trasporto: pacchetto standard per l'estero che garantisce una consegna sicura

- Porto di spedizione: Qingdao, provincia di Shandong

- Adatto per applicazioni di linee di produzione di condotti elettrici

- Ideale per la produzione di linee di produzione di condotti per la protezione dei cavi

- Linea di estrusione di plastica per tubi corrugati a parete singola di alta qualità

Specifiche tecniche

| Parametro |

Specifica |

| Porto |

Qingdao, provincia di Shandong |

| Materia prima consigliata |

PE, PP, PVC |

| Modalità di raffreddamento |

Raffreddamento ad acqua |

| Pacchetto di trasporto |

Pacchetto standard per l'estero |

| Sistema di controllo |

PLC |

| Materiale adatto |

HDPE, PE, PVC, PP |

| Motore principale |

Siemens |

| Strato |

Parete singola, doppia parete |

Applicazioni e settori

La linea di estrusione di tubi corrugati a parete singola HUASU (modello SBG) è un impianto di tubi corrugati in plastica altamente efficiente e affidabile certificato con gli standard CE e ISO. Questa macchina per la produzione di tubi corrugati per il drenaggio è progettata per offrire prestazioni superiori nella produzione di tubi corrugati a parete singola e doppia.

Applicazioni principali:

• Sistemi di irrigazione agricola

• Drenaggio urbano e gestione delle acque reflue

• Protezione dei cavi e produzione di condotti elettrici

• Sviluppo di infrastrutture e costruzioni

• Soluzioni di drenaggio industriale

Con una fascia di prezzo da 10K USD a 1000K USD a seconda della configurazione, questa apparecchiatura offre un eccellente rapporto qualità-prezzo con una capacità di fornitura di 100 set all'anno. La consegna è in genere di 60-90 giorni con termini di pagamento flessibili tra cui T/T e L/C e una quantità minima d'ordine di 1 set.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews